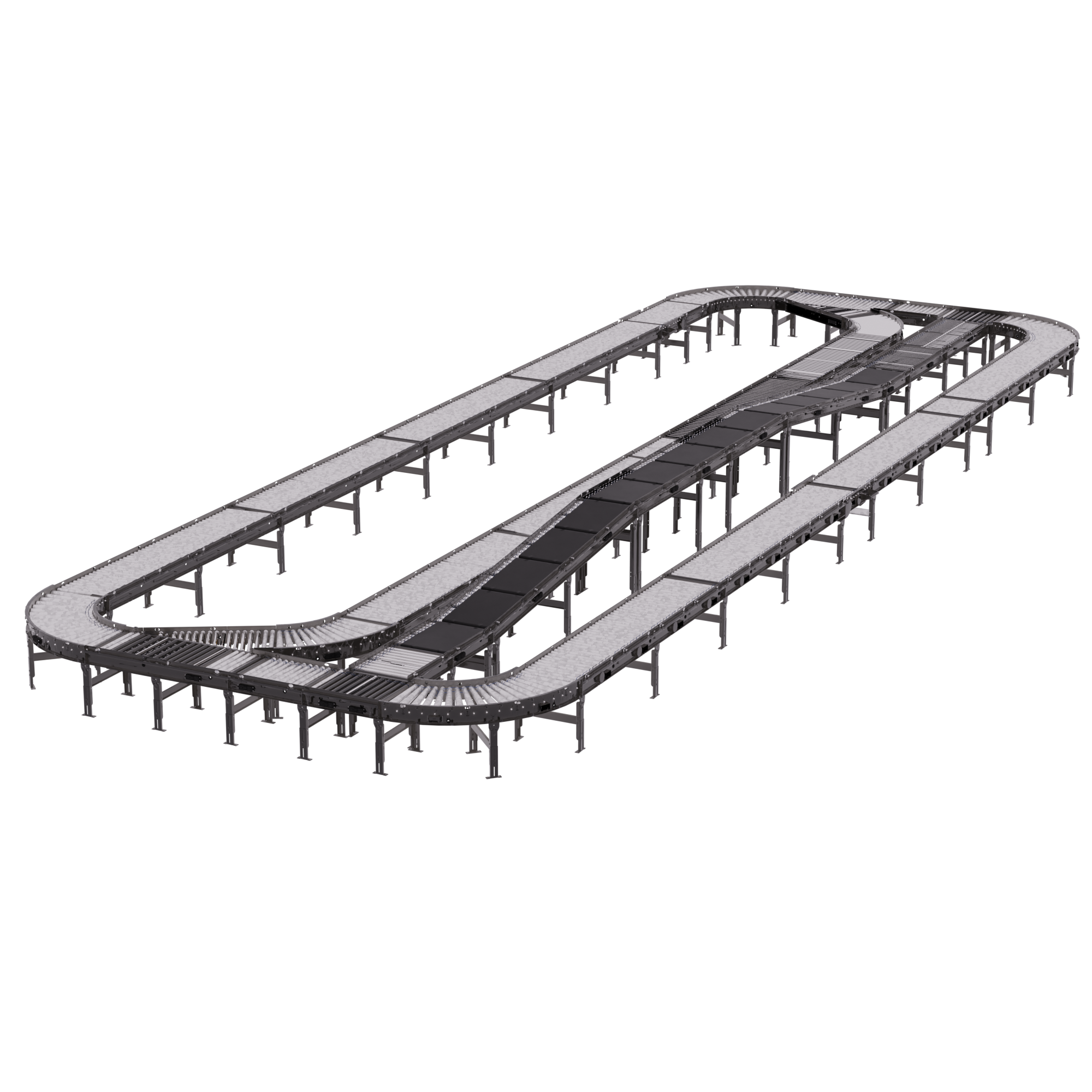

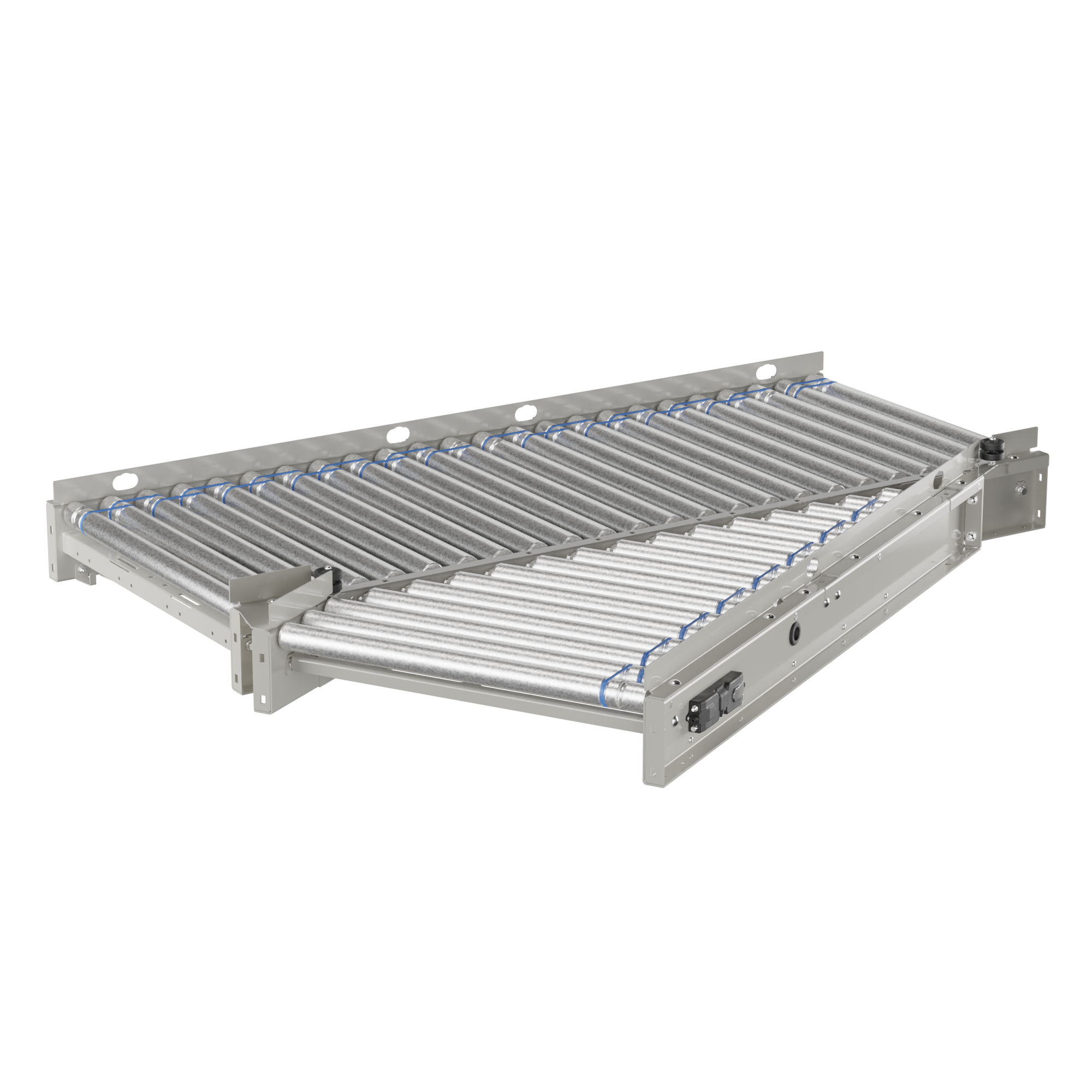

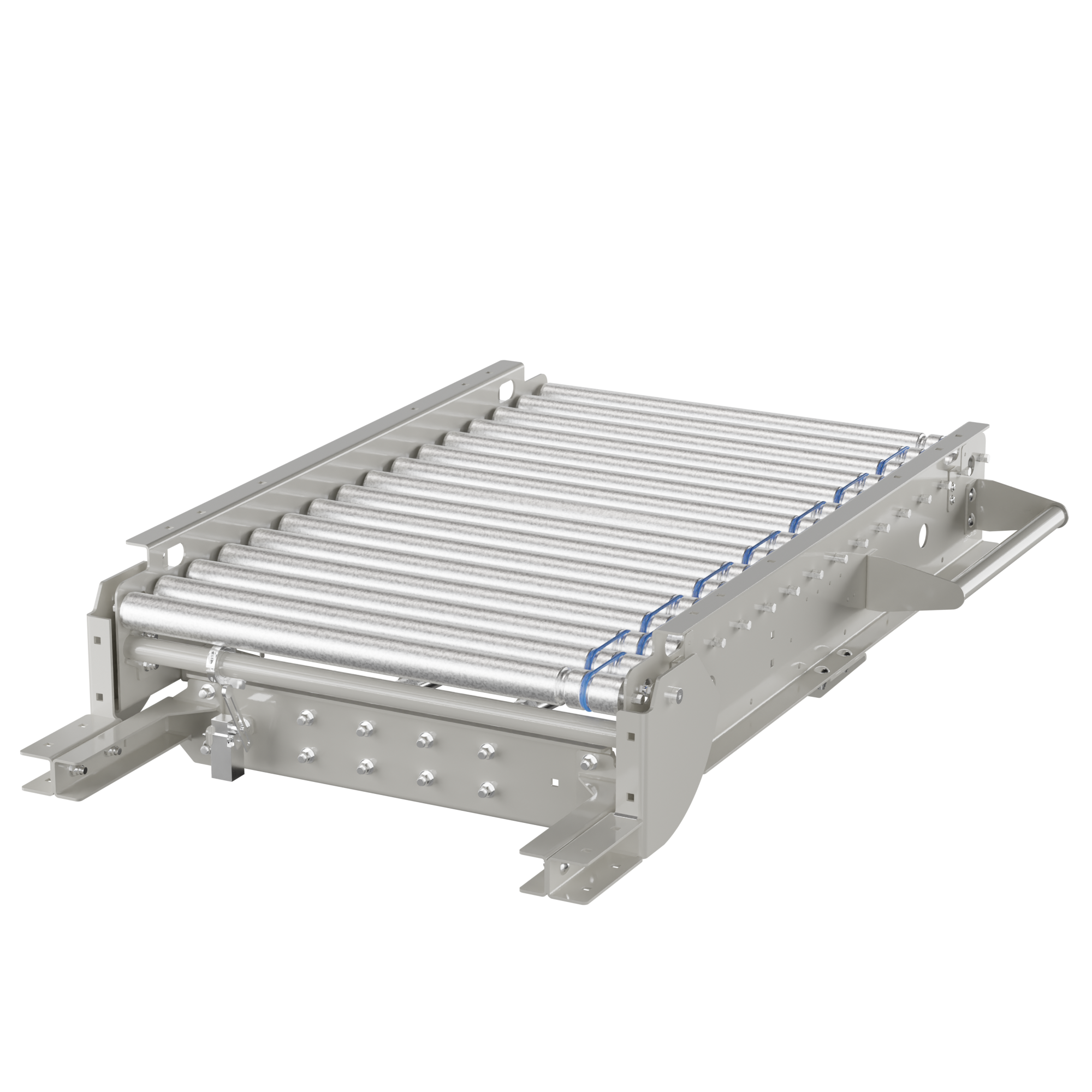

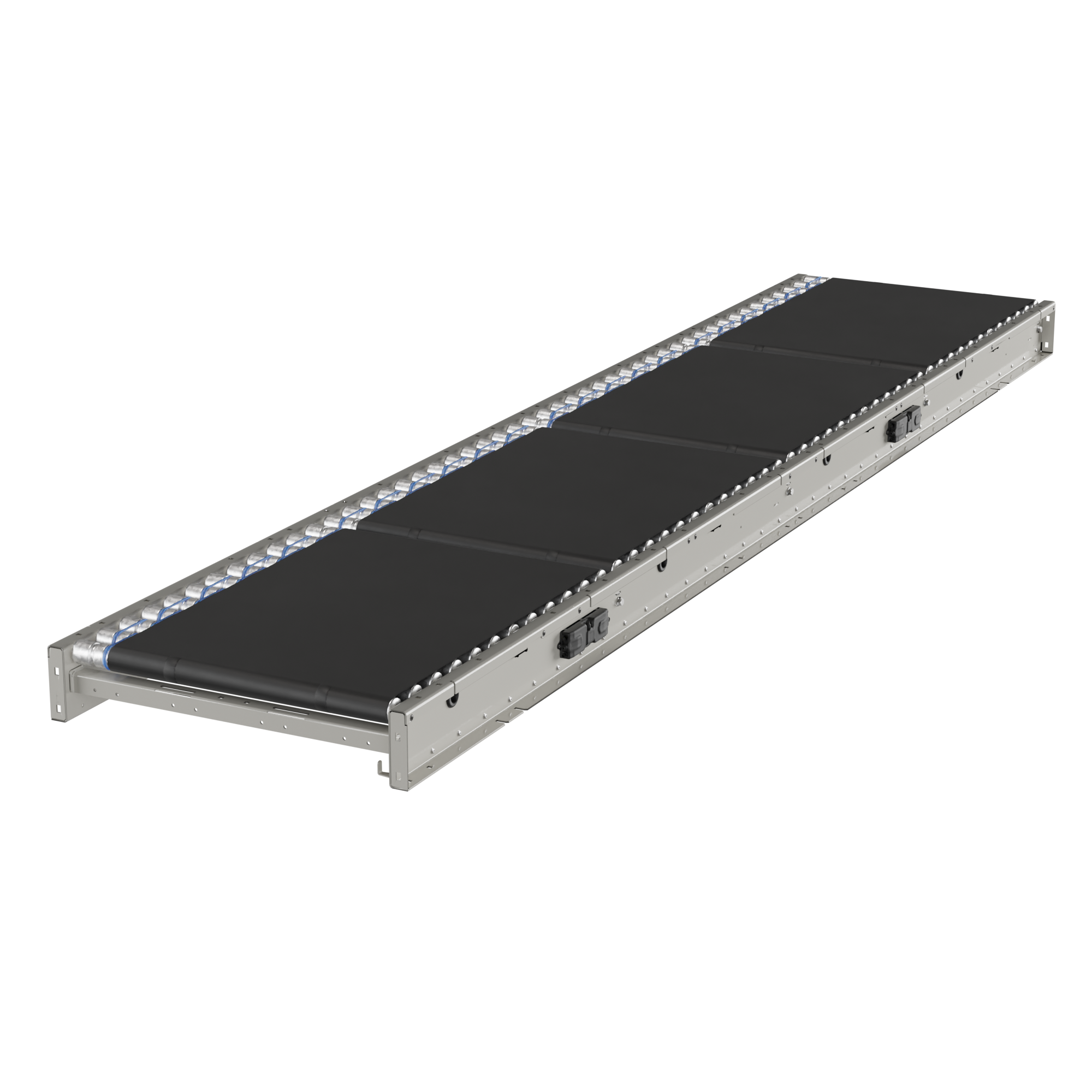

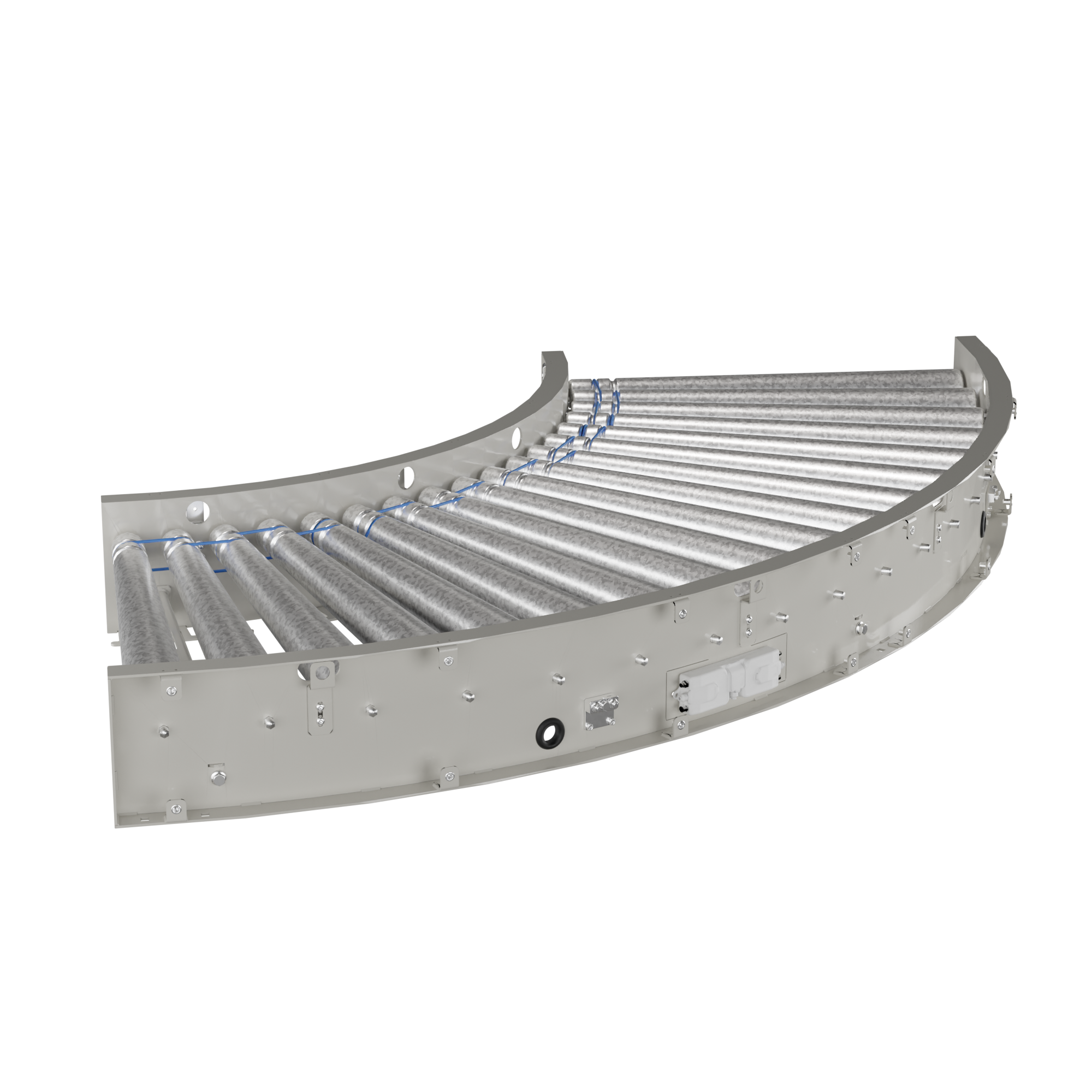

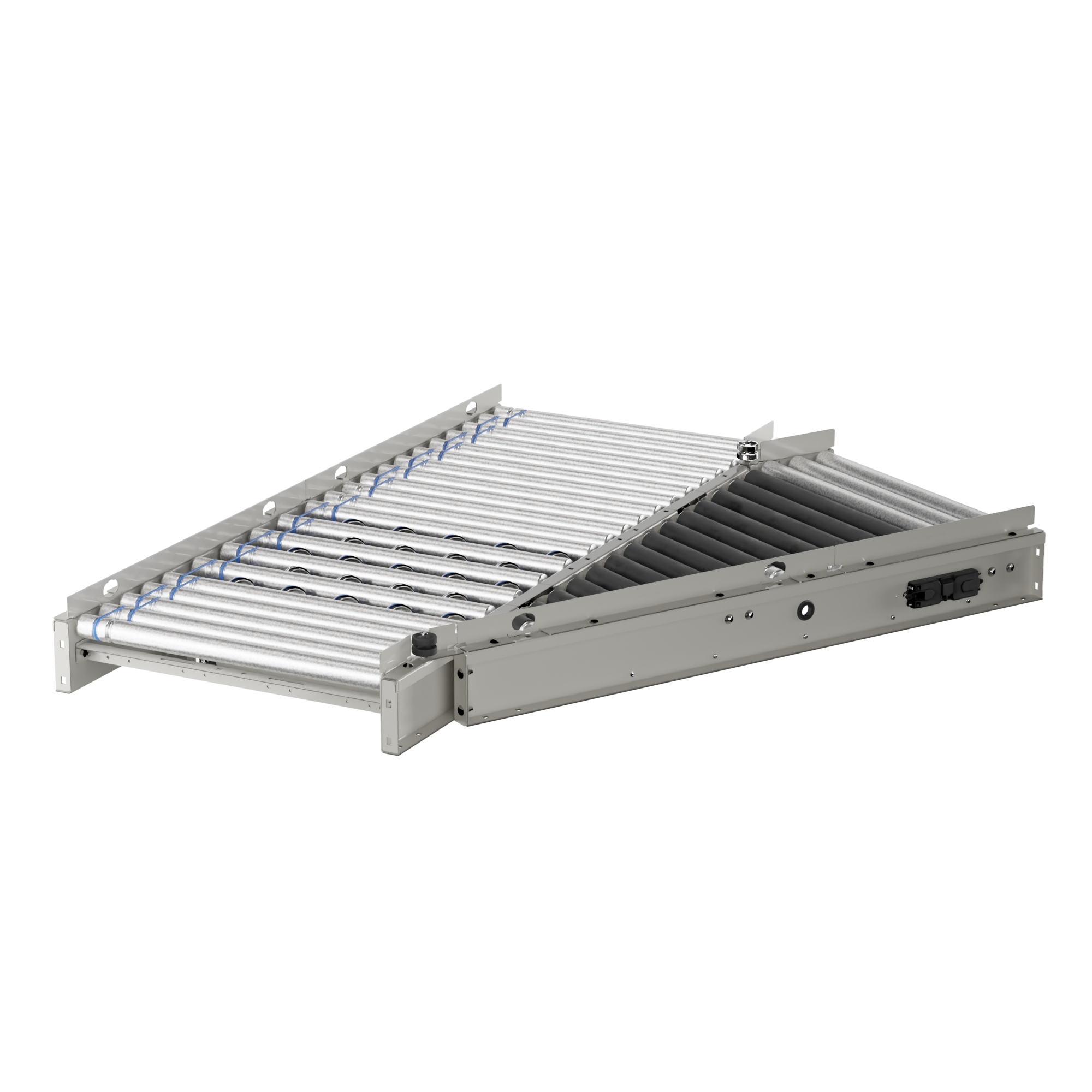

Motor Driven Roller (MDR) Conveyor

Motor Driven Roller (MDR) conveyors from Talos Engineered Products are engineered to deliver energy-efficient, flexible, and quiet material handling with true accumulation and precise zone control. MDR systems are built to keep product moving smoothly while reducing downtime, energy consumption, and maintenance requirements — making them ideal for distribution, fulfillment, parcel handling, and manufacturing environments.

key features and benefits

Energy Efficient

MDR zones only run when product is present, significantly reducing power consumption compared to continuously driven systems.

Quiet and Low Maintenance

With fewer moving parts and low-voltage DC drives, MDR systems operate quietly and require less maintenance, lowering total cost of ownership.

Seamless integration

MDR systems integrate with merges, diverts, transfers, sortation equipment, chutes, and other conveyors, providing flexible solutions for complex material handling needs.

Modular and Customizable

Talos MDR conveyors are customized for layout, width, roller centers, zone lengths, and speed requirements, making them adaptable to a wide range of applications.

How MDR delivers smarter conveying is through low-voltage, zone-controlled technology that adapts to real-time product flow. By running only when needed, MDR systems reduce operating costs while improving throughput and system responsiveness—making them ideal for high-volume, fast-paced distribution environments.

How MDR Delivers Smarter Conveying

Low-voltage, zone-controlled technology adapts to real-time product flow. MDR conveyor systems utilize 24V low-voltage motorized rollers that operate within individual conveyor zones. This zone-based design allows the system to respond dynamically to changing product flow, ensuring smooth, controlled movement without relying on a continuously running drive.

Individual zones activate only when product is present. Each MDR zone is equipped with sensors that detect the presence of cartons or totes. When product enters a zone, the motorized roller activates to move it forward, then shuts off once the product exits. This on-demand operation improves efficiency while maintaining consistent flow throughout the system.

Reduced energy consumption compared to traditional conveyor systems. Because MDR conveyors operate only when product is present, they use significantly less energy than line-shaft or belt-driven conveyors that run constantly. This reduction in power usage lowers utility costs and supports sustainability initiatives without sacrificing performance.

Lower operating and maintenance costs over the life of the system. With fewer moving parts, no chains or belts, and reduced mechanical wear, MDR systems require less maintenance over time. The result is fewer service interruptions, lower repair costs, and improved long-term reliability.

CONNECT WITH AN MDR EXPERT

From concept to installation, Talos MDR experts work alongside your team to deliver conveyor solutions that support throughput, reliability, and long-term growth.